What is an example of a physical hazard food handlers? This dives into the crucial topic of food safety, focusing on the dangers of physical contaminants in food preparation. Understanding these hazards is vital for preventing foodborne illnesses and ensuring safe food handling practices. From dropped metal shavings to broken glass, various physical objects can easily contaminate food if not properly managed.

This guide will cover the different types of physical hazards, their sources, how to prevent them, and case studies of real-world incidents. We’ll also explore the importance of training programs and visual aids in enhancing awareness and reducing risks.

Defining Physical Hazards in Food Handling: What Is An Example Of A Physical Hazard Food Handlers

Right, so, physical hazards in food are basically any solid, liquid, or semi-solid object that can contaminate food and make people sick. It’s a pretty straightforward concept, but understanding the nuances is key to nailing food safety.Physical hazards are different from other hazards like chemical or biological ones. Chemical hazards are things like cleaning solutions, and biological hazards are things like bacteria.

Physical hazards, as the name suggests, arephysical* things. Think of it as a clear distinction in the nature of the contaminant.

Characteristics of Physical Hazards

Physical hazards are typically non-soluble in food, meaning they don’t mix in or dissolve. They are often visible and easy to spot, but their presence can still cause a big issue if not properly managed. Their physical form also makes them different from other hazards, like chemical hazards that could dissolve or react in the food, and biological hazards that are usually microscopic.

Physical hazards in food handling are foreign objects that contaminate food. Examples include metal shavings, glass fragments, or pieces of wood. Proper food safety protocols, including meticulous hygiene practices and the provision of appropriate accommodation in Villers-Bretonneux, France, such as this comprehensive selection of hotels and guesthouses , are crucial to mitigate such risks. Ensuring a safe and clean environment for food preparation is paramount to prevent these physical hazards.

This means that they can be easily identifiable through inspection and appropriate prevention measures can be taken to eliminate the risk of contamination.

Examples of Physical Hazards

A range of items can be physical hazards in food prep. Food handlers need to be vigilant about anything that could contaminate food. Think about these examples:

- Metal shavings from equipment

- Glass fragments from broken containers

- Hair, fingernails, or skin flakes from food handlers

- Stones or dirt from unwashed produce

- Plastic pieces from packaging or utensils

Prevention Methods for Physical Hazards

Implementing proper procedures can effectively reduce the risk of physical hazards. By establishing clear guidelines and protocols, we can significantly minimize the chance of contamination, ensuring food safety. For example, regular maintenance of equipment, careful handling of ingredients, and strict adherence to hygiene protocols are crucial steps in prevention.

Table of Physical Hazards

This table summarises the different types of physical hazards, their potential sources, and the prevention methods to minimise the risk.

| Hazard Type | Description | Potential Source | Prevention Methods |

|---|---|---|---|

| Metal Shavings | Small pieces of metal from equipment | Damaged or poorly maintained equipment, improper cleaning | Regular equipment maintenance, using screened utensils, careful cleaning and inspection of equipment |

| Glass Fragments | Broken glass pieces | Broken glass containers, improper handling of glassware | Using undamaged containers, regular inspection of containers, avoiding breakage |

| Hair, Fingernails, Skin | Human hair, fingernails, or skin particles | Food handlers with poor hygiene practices, lack of appropriate protective gear | Strict adherence to hygiene standards, wearing appropriate protective gear, regular hand washing |

| Stones/Dirt | Stones or dirt particles | Unwashed or contaminated produce, unclean surfaces | Thorough washing of produce, cleaning of surfaces, using proper containers for ingredients |

| Plastic Pieces | Small pieces of plastic | Damaged packaging, broken utensils | Using undamaged packaging, using appropriate utensils, proper disposal of damaged packaging |

Common Sources of Physical Hazards

Right, so we’ve established that physical hazards are a major no-no in food prep. Now, let’s dive into the

- where* and

- why* these nasties pop up. Knowing the common sources is crucial for prevention, folks.

Understanding the origins of these hazards allows us to implement robust control measures. This, in turn, reduces the risk of contaminated grub and keeps our customers safe, which is the name of the game.

Frequent Sources of Physical Contamination

A good grasp of where physical hazards originate is key to mitigating risks. These aren’t just random occurrences; they often stem from predictable sources within the kitchen environment.

Contamination Pathways

Food contamination by physical hazards often involves direct contact or indirect transfer. A dropped metal shard could pierce a sandwich. A stray hair in a bowl of salad is a no-go, too. It’s about how these items get into the food, not just their presence.

Common Physical Hazards and Associated Foods

| Source | Potential Contaminant Foods | Risk Description |

|---|---|---|

| Metal fragments (e.g., bent or broken utensils, loose screws, etc.) | Sandwiches, salads, ready-to-eat meals | Sharp metal can pierce the food, causing injury or discomfort to the consumer. |

| Glass fragments (e.g., broken jars, containers) | Sauces, chutneys, desserts | Sharp glass can cut the consumer. Ingesting glass is extremely dangerous. |

| Plastic fragments (e.g., broken utensils, container pieces) | Salads, soups, ready-to-eat foods | Plastic pieces can cause discomfort or be harmful if ingested. |

| Wood fragments (e.g., splinters from cutting boards, chopping blocks) | Salads, fruits, vegetables | Wood splinters can cause injury or discomfort, especially if ingested. |

| Hair (e.g., human, animal) | Salads, cooked dishes, ready-to-eat meals | Hair is a disgusting contaminant, and it’s easy for consumers to choke on it. |

| Stones, dirt, insects | Salads, fruits, vegetables, raw meats | Stones, dirt, and insects can cause food poisoning or injury. |

| Packaging materials (e.g., staples, tape, labels) | Prepared meals, sandwiches, salads | Packaging components can be a source of choking hazards and physical injury. |

Impact of Poor Hygiene and Lack of Control

Poor hygiene practices significantly increase the risk of physical contamination. Imagine a food prep area where cleaning isn’t prioritized. This creates a breeding ground for physical hazards, increasing the chance of contamination. A lack of proper control measures, like inadequate inspection of equipment or ingredients, can lead to hazards slipping through the cracks. This is a major fail.

Poor hygiene and lack of control are significant contributors to physical contamination risks.

Examples of Physical Hazards

Right, so we’ve established that physical hazards are a real threat to food safety. Now, let’s drill down into the specifics, looking at theactual* stuff that could cause problems in a food prep environment. Knowing the types and how to avoid them is key to keeping things squeaky clean.

A Rundown of Common Physical Hazards

Physical hazards in food handling are, basically, any foreign object that ends up in the food. These contaminants can range from relatively benign to seriously dangerous, and the potential impact on the end product is crucial to understanding. Effective prevention is the name of the game here.

List of Physical Hazards

These are some of the most common physical hazards encountered in food preparation. Understanding their presence and how to stop them is vital for maintaining food safety standards.

- Metal fragments (e.g., screws, nails, staples): These are pretty obvious dangers, often introduced during the handling of tools or packaging. They can cause severe injury if ingested.

- Glass shards (e.g., broken bottles, jars): Glass is a particularly nasty hazard, given its sharp edges and potential for causing cuts or internal injuries. It’s vital to ensure proper handling and disposal of glass containers.

- Wood chips (e.g., from cutting boards, wooden utensils): While less severe than glass or metal, wood chips can still cause problems. They’re a contaminant, and people can get grossed out by them in their food.

- Plastic fragments (e.g., broken containers, packaging): Similar to wood, plastic fragments aren’t necessarily lethal, but they can be unpleasant to eat. Careful handling and storage are essential.

- Stones (e.g., from produce): Stones, especially those from fruits and vegetables, can cause blockages in the digestive system if swallowed. Thorough cleaning is paramount.

- Hair (e.g., from food handlers): Food handlers’ hair, or hair from other sources, can be a significant contaminant. Personal hygiene is critical to avoid this hazard.

- Bandages, and other textiles (e.g., from cleaning cloths): These are another type of foreign matter that can make its way into food. Contamination can occur if proper hygiene and cleaning procedures aren’t followed.

- Metal shavings (e.g., from machinery): Sharp metal shavings are a serious hazard if ingested. Regular maintenance of equipment is a must.

- Bones (e.g., from meat preparation): Bones are an obvious concern when dealing with meat. Careful preparation and separation procedures are vital.

- Foreign objects (e.g., coins, jewellery, insects): A catch-all category, these could be anything not intended to be in the food. This highlights the importance of general cleanliness and awareness.

Hazard Analysis Table

This table summarises the potential hazards, their description, scenarios where they might appear, and how to prevent them.

| Hazard | Description | Example Scenarios | Prevention Measures |

|---|---|---|---|

| Metal Fragments | Sharp, potentially harmful pieces of metal. | A loose screw falls into a batch of salad. | Regular inspection of equipment, secure storage of tools. |

| Glass Shards | Sharp fragments of glass. | A broken bottle is not properly discarded and contaminates a food product. | Proper handling and disposal of broken glass, use of shatterproof containers. |

| Wood Chips | Small pieces of wood. | Wood chips from a cutting board contaminate a salad. | Use of clean, undamaged cutting boards, proper cleaning of utensils. |

| Plastic Fragments | Small pieces of plastic. | Broken plastic packaging contaminates a food product. | Use of appropriate packaging, proper handling and disposal of packaging. |

| Stones | Hard, small stones from produce. | Stones in a batch of spinach. | Thorough cleaning of produce, proper sorting. |

| Hair | Human hair, or hair from other sources. | Hair from a food handler contaminates a meal. | Strict personal hygiene standards, hairnets. |

| Bandages/Textiles | Fabric or material. | Contamination from a dirty cleaning cloth. | Regular cleaning of equipment and work areas, proper disposal of contaminated materials. |

| Metal Shavings | Small pieces of metal. | Metal shavings from a machine contaminate food. | Regular maintenance of equipment, using appropriate tools. |

| Bones | Animal bones. | Bones in a meat dish. | Proper separation and removal of bones from food products. |

| Foreign Objects | Any non-food items. | A coin in a food product. | Strict adherence to hygiene protocols, regular checks for foreign objects. |

Severity and Impact

The severity of physical hazards varies greatly, depending on the size, shape, and material of the contaminant. Some hazards, like metal fragments, pose a direct threat to health. Others, like small plastic pieces, might be more of an annoyance. The impact on food products depends on the type of food. A whole piece of glass in a cake is clearly a bigger problem than a few wood chips in a stew.

Prevention and Control Measures

Right, so we’ve covered the

- what* and

- where* of physical hazards in food prep. Now, let’s crack on to how we can

- stop* them from turning into a major food safety fail. Preventing these hazards is key for maintaining a safe and hygienic environment, which ultimately translates to happy customers and a good rep for the business.

Strategies for Preventing Physical Hazards

Effective prevention relies on a multi-pronged approach. It’s not just about one single thing; it’s about a whole system of checks and balances. This involves meticulous planning, rigorous procedures, and constant vigilance from all staff. Think of it like a well-oiled machine – every part needs to function perfectly for the whole thing to run smoothly.

Employee Training and Awareness

Staff training is absolutely crucial. It’s not just about showing them the rules; it’s aboutinstilling* the importance of safe practices. A well-trained team is a proactive team, and that translates into a lower risk of incidents. A good training program should cover everything from proper food handling techniques to the correct procedures for identifying and reporting potential hazards.

Effective Procedures to Reduce Risks

Implementing robust procedures is paramount. These procedures should be clearly defined, easily understood, and consistently applied by everyone involved. Regular audits and reviews of these procedures are also essential to ensure they remain effective and up-to-date.

Safety Protocols for Food Handlers

Following a comprehensive list of safety protocols is critical. These protocols should cover everything from personal hygiene to proper storage and handling of ingredients. A well-defined protocol is a powerful tool in minimizing the risk of physical hazards. Think about it: clear instructions are the backbone of safe food handling.

Physical hazards in food handling environments pose a significant risk to food safety. One example includes improperly stored or damaged equipment, such as a dropped knife or a cracked container, that can contaminate food. Ensuring proper maintenance and handling procedures is crucial. Businesses in the food service industry should engage with insurance brokers in San Jose CA, such as those found at insurance brokers in san jose ca , to develop comprehensive risk management strategies, which can mitigate the risk of physical hazards like these, thereby protecting both the business and the consumer.

Table of Prevention Methods

| Prevention Method | Description | Implementation Steps | Benefits |

|---|---|---|---|

| Regular Cleaning and Sanitization | Maintaining a clean and sanitary environment is crucial. This includes regular cleaning of work surfaces, equipment, and storage areas. | Schedule regular cleaning sessions, use appropriate cleaning agents, and ensure thorough drying of surfaces. Include the use of colour-coded cleaning schedules to avoid cross-contamination. | Reduces the risk of contamination from foreign objects and promotes a hygienic environment. |

| Proper Storage of Ingredients | Storing ingredients in designated areas prevents them from being mixed up or accidentally dropped into food. | Use labeled containers, keep areas organized, and ensure proper temperature control (especially for potentially hazardous foods). Designate specific areas for each type of ingredient. | Reduces the risk of foreign objects being incorporated into food products. Helps maintain quality and safety of ingredients. |

| Regular Inspections | Regular checks of work areas and equipment for potential hazards is a must. | Establish a schedule for inspections, train staff on what to look for, and implement corrective actions if needed. Utilize checklists for consistency. | Identifies and mitigates potential hazards before they lead to incidents. |

| Employee Supervision | Monitoring staff for adherence to safety protocols is essential. | Establish clear communication channels, provide regular feedback, and promptly address any observed safety concerns. Utilize observation checklists to track compliance. | Promotes consistent adherence to safety protocols, and enables early intervention to correct any unsafe behaviour. |

| Waste Management | Effective waste disposal is critical to prevent contamination and the introduction of foreign objects. | Ensure designated waste bins are readily available, and they are emptied regularly. Maintain separate bins for different types of waste. | Reduces the risk of contamination and ensures proper disposal of potentially hazardous materials. |

Case Studies of Physical Hazard Incidents

Understanding real-world instances of physical hazards in food handling is crucial for preventative measures. These case studies highlight the importance of rigorous risk assessment and the potential consequences of inadequate safety protocols. Learning from past mistakes is paramount to fostering a safer food production environment.Examining actual incidents provides invaluable insight into the root causes of physical contamination. By dissecting the circumstances, consequences, and subsequent corrective actions, we can develop more robust safety protocols to minimise the risk of future occurrences.

This approach empowers food handlers and managers to make informed decisions based on practical experience.

Real-Life Incident Examples

These examples illustrate the diverse ways physical hazards can compromise food safety and highlight the critical need for vigilant prevention strategies.

| Incident | Cause | Consequences | Corrective Actions |

|---|---|---|---|

| Metal Shard Contamination | A faulty piece of equipment, like a poorly maintained slicer, released a metal shard into a batch of pre-cut vegetables. Lack of routine maintenance checks contributed to the issue. | Several customers reported gastrointestinal issues after consuming the contaminated vegetables. The company faced significant reputational damage and a substantial financial penalty. The affected batch had to be recalled and destroyed, incurring substantial losses. | The company implemented a rigorous equipment maintenance schedule, including more frequent inspections and preventative repairs. Staff received comprehensive training on identifying and reporting potential hazards. The supplier of the faulty equipment was also contacted for corrective action. |

| Glass Fragment in Salad | A broken glass container in the salad preparation area was not promptly addressed, resulting in glass fragments contaminating the salad. Inadequate cleaning protocols and a lack of attention to detail contributed to this incident. | A small number of customers experienced minor injuries from the glass shards. The restaurant suffered a significant loss of customer trust and reduced sales. The local health authority issued a warning. | The restaurant reinforced its cleaning protocols, ensuring thorough checks of all equipment and surfaces. Stricter procedures were implemented to manage and dispose of broken glass. Staff training focused on identifying and reporting potential hazards. |

| Foreign Object in a Meal | A piece of wood, possibly from a pallet, was inadvertently mixed with the ingredients of a prepared meal. Lack of adequate visual inspection during the meal preparation process was a contributing factor. | A customer discovered a piece of wood in their meal and reported it to the restaurant management. The incident resulted in negative press coverage and reduced customer confidence. The establishment faced a significant loss of customer trust and reputational damage. | Enhanced visual checks at each stage of the meal preparation were implemented. The restaurant staff received thorough training on the proper handling and inspection of raw materials. A regular audit system was introduced to identify and mitigate the risk of foreign objects. |

Importance of Thorough Risk Assessments

A thorough risk assessment is fundamental to identifying potential physical hazards. This involves a systematic evaluation of all aspects of the food handling process. It’s not just about identifying the

- what* but also the

- how* and the

- why*.

Proactive risk assessments should consider factors such as equipment maintenance, material handling, and staff training. A comprehensive risk assessment should consider potential risks from the incoming raw materials to the final product. Identifying these risks early allows for the development of preventative strategies and reduces the probability of future incidents.

Improving Safety Protocols

Lessons learned from these incidents can significantly improve safety protocols. Regular audits, improved training programs, and a culture of vigilance can prevent similar issues from occurring. Implementing these measures will ensure that the food handling process is safer and more efficient.

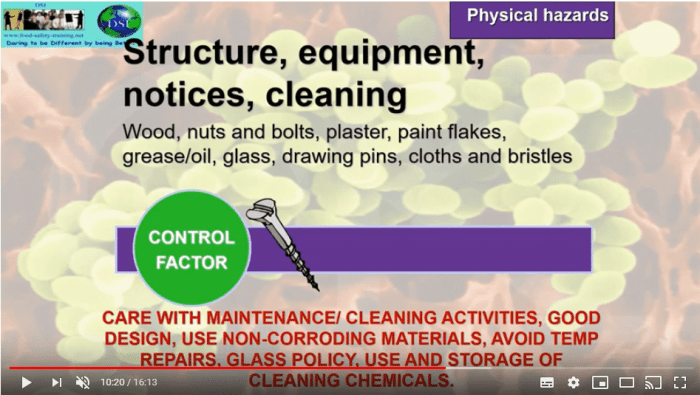

Visual Representation of Hazards

Visual aids play a crucial role in enhancing food safety training for kitchen staff. By providing clear and concise visual representations of potential physical hazards, we can significantly improve their understanding and ability to prevent incidents. This approach goes beyond simply stating the rules; it fosters a deeper comprehension of the practical implications of each hazard.Visual representations, like diagrams and illustrations, are far more memorable than simply reading about hazards.

They allow for quicker assimilation of information and aid in the development of proactive safety habits, making food handlers more vigilant and reducing the risk of accidents.

Visual Representations of Different Physical Hazards, What is an example of a physical hazard food handlers

Visual aids can effectively illustrate various physical hazards, making them instantly recognizable to food handlers. A clear depiction of a metal shard within a food product can be far more impactful than a written description, encouraging immediate recognition and the implementation of preventive measures.

Visual Aids for Enhancing Hazard Awareness

A well-designed visual aid can transform a theoretical concept into a tangible, relatable image. For example, a diagram illustrating a broken glass embedded in a batch of salad can instantly highlight the potential risk associated with poor cleaning practices. These visuals act as powerful reminders of the importance of meticulous handling and proper sanitation.

Table of Visual Aids

| Visual Aid | Description | Potential Use |

|---|---|---|

| Diagram of a metal fragment in a food product | A simple illustration of a piece of metal embedded in a portion of food, like a salad or cooked meat. | To illustrate the potential hazard of metal contamination from equipment or packaging. |

| Illustration of a chipped or broken knife blade | A graphic representation of a chipped or broken knife blade, highlighting the potential for lacerations. | To emphasize the importance of knife maintenance and safe handling. |

| Flowchart depicting correct cleaning procedures | A visual representation of the steps involved in the safe cleaning of equipment and surfaces. | To demonstrate the proper procedure for preventing physical contamination. |

| Image of a contaminated food product with foreign objects | An image showcasing a food item with foreign objects such as hair, plastic, or wood fragments. | To demonstrate the hazards associated with poor hygiene and inadequate waste management. |

| Diagram of a food preparation area with highlighted safety zones | A diagram of a kitchen, highlighting designated areas for different tasks. | To encourage appropriate placement of equipment and materials to prevent cross-contamination and physical hazards. |

Designing Visual Aids

Visual aids should be simple, clear, and easily understood. Use bold colours and clear Artikels to ensure that the hazard is readily apparent. Consider using icons or symbols to represent key concepts or actions. Illustrations should be easy to interpret, even for individuals with varying levels of literacy.

Incorporating Visual Aids into Training Programs

Visual aids should be strategically integrated into training programs. Show the illustrations during the initial presentation of the hazard and then reinforce the message by including them in practical exercises and real-life scenarios. This method aids in retaining information, improving understanding, and making the learning experience more effective and engaging. Include quizzes and assessments to test knowledge retention after each presentation of the hazard.

For example, after showing a diagram of a broken knife blade, test understanding with questions like “How can the use of dull knives lead to potential cuts?” or “What steps can be taken to prevent this hazard?” Active recall exercises enhance knowledge application and reinforce the importance of visual aids.

Food Handler Training Programs

Right, so we’ve covered the basics of physical hazards in food handling. Now, let’s drill down on how to actually train folks to spot and avoid these nasties. Effective training programs are key to preventing incidents, and we need to make sure the training is engaging and sticks.

Sample Training Program Module on Physical Hazards

This module is designed to be a core component of a broader food safety training program. It focuses on equipping food handlers with the knowledge and skills to identify, control, and prevent physical hazards. The module should be practical, incorporating real-world examples, to make the concepts memorable.

Importance of Interactive Elements

Interactive elements in training programs are crucial for boosting engagement and knowledge retention. Activities like quizzes, case studies, and group discussions actively involve learners and encourage critical thinking. This active participation leads to better understanding and application of the concepts in the real world. For instance, a role-playing exercise where trainees act out scenarios involving physical hazards can make the learning process more concrete.

Best Practices for Engaging Training Materials

To craft engaging and informative training materials, employ diverse methods. Visual aids, like clear diagrams and images of common physical hazards, can enhance understanding. Real-life case studies or scenarios, based on authentic incidents, can make the training relatable. Furthermore, including interactive elements, such as quizzes and group discussions, helps to make the learning process more active and memorable.

Remember, keep the language simple and avoid jargon to ensure everyone can grasp the concepts.

Training Program Module Structure

| Training Topic | Learning Objectives | Activities | Evaluation Methods |

|---|---|---|---|

| Identifying Physical Hazards | Recognize common physical hazards in food preparation areas. | Hands-on hazard identification exercise in a simulated kitchen environment. | Quiz on identifying physical hazards. |

| Controlling Physical Hazards | Understand preventive measures to minimize the risk of physical contamination. | Group discussion on preventive measures for different scenarios. Role-playing exercise. | Observation of trainee application of preventive measures in a simulated setting. |

| Preventing Physical Hazards | Develop strategies to prevent the introduction of physical hazards into the food chain. | Case studies of real-world incidents. Design of preventative strategies in a small group setting. | Written report on case studies and proposed solutions. |

| Personal Hygiene and Safety Procedures | Implement safe handling practices to avoid accidental contamination. | Interactive presentation on personal hygiene practices. | Practical demonstration of proper handwashing techniques. |

Adapting the Program for Different Audiences and Situations

The training program can be tailored for various audiences and contexts. For instance, a program for new hires might focus on the basics, while a refresher course for experienced staff might emphasize specific hazards relevant to their work area. The duration of the program can also be adjusted depending on the needs of the group. The training module can be adapted to specific industry settings, taking into account unique equipment and procedures.

Consider the language barriers and learning styles of different participants to ensure inclusivity and effectiveness.

Closing Summary

In conclusion, preventing physical hazards in food handling requires a multifaceted approach. From meticulous cleaning and maintenance to comprehensive employee training and strict adherence to safety protocols, a proactive strategy is key to minimizing risks and ensuring the safety of food products. By understanding the potential hazards, their sources, and preventive measures, food handlers can significantly reduce the likelihood of contamination and contribute to a safer food environment.

FAQ Summary

What are some common physical hazards found in food preparation areas?

Common physical hazards include metal shavings, glass fragments, hair, bandages, and even pieces of jewelry. These items can easily contaminate food if not properly controlled during food preparation.

How can poor hygiene increase the risk of physical hazards?

Poor hygiene, like not washing hands frequently or not maintaining a clean work environment, can lead to physical hazards contaminating food. If food handlers don’t follow proper hygiene procedures, it increases the risk of physical contaminants ending up in the food.

What are some effective prevention measures for physical hazards?

Effective prevention measures include regular cleaning and sanitation of the work area, proper storage of tools and equipment, and employee training on proper handling procedures. Using color-coded containers for different food items can also help prevent contamination.

What is the role of employee training in preventing physical hazards?

Employee training plays a crucial role in preventing physical hazards. Training programs should cover proper food handling techniques, hygiene practices, and the identification of potential physical hazards. This knowledge empowers food handlers to take preventative actions and reduce contamination risks.